Quid faciam fabrica mechanica apparatu requiritur ad pre-tank coetus in AAC productio linea curare accurate mechanica apparatu per pre-tank Pecunia processus, comprehendo ad mensuram, figura recognition et adjunctio accurate in codicellos?

I. Blank mole measurement

(I) summus praecisione mensuræ apparatu

Uti summus praecisione mensuræ instrumenta, ut tres-coordinare mensuræ machinis, laser scanners, etc., quod potest providere accurate mole data.

Calibrate in mensuræ apparatu regulariter ut accurate ad mensuram results.

(II) lectio mensura modum

Select oportet mensuram modum secundum characteres et requisitis in blank. Exempli gratia, quia magna-amplitudo codicellos, non-contactus mensurae modi ut laser scanning potest esse; Nam dimensiones quae requirere accurate ad plures decimales locis, summus praecisione contactus mensura instrumenta debet esse.

(III) Data recording et analysis

Recordarentur in notitia de se mensuram in detail et praestare actuariis analysis ad opportune invenire et rectam potentiale measurement errores.

II. Figura recognition

(I) Trajectoria modum et formatam modum

Uti Trajectory Method (tool Tip Trajectoria Method) vel formatam modum (per geometrica figura formatam tool) ad figura recognition. Hi modi potest consequi accurate recognitionem de blank figura per subtiliter imperium mechanica apparatu.

Cum per haec modi, necesse est ut stabilitatem et accurate mechanica apparatu vitare figura recognitionem errores per apparatu vibrationis vel gerunt.

(II) Image Processing Technology

Inducere imaginem processui technology, capere imago blank per a camera et alia apparatu, et uti imaginem recognitionem algorithm ad identify figura de blank. Hoc modum potest cito et verius identify figura characteres in blank.

III. Adjunctio accurate

(I) Intelligentes Party

Develop aut adopt est intelligentes partes ratio, qui potest statim coetus secundum magnitudinem et figura notitia de blank. Perficiendum accurate et efficientiam ad algorithm optimization et notitia analysis.

(II) Manual Review

De ex automated coetus, addere manual review link. Peritus operators review ad adjunctio est ut accurate ad adjunctio.

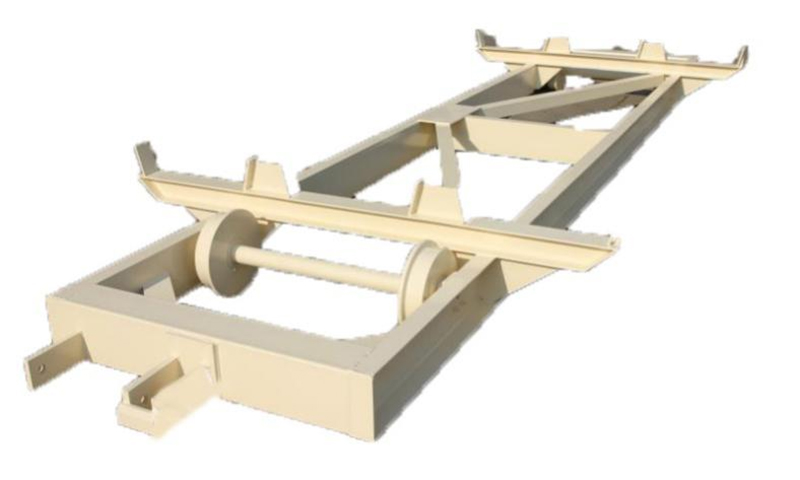

(III) Fixture Design

Design rationabile fixtures ut stabilitatem et reliability de blank in coetus processus. Fixture dignum stabilitatem et reliability requisita workpiece positioning et sufficienti onus portantes aut clamping vires.

Quomodo potest mechanica apparatu elit requiritur ad pre-oldle adjunctio in AC productio linea curare stabilitatem et reliability mechanica apparatu et vitare impulsum downtime in productionem?

I. Design et Vestibulum Tempus

Optimised Design:

Per consilio scaena mechanica apparatu, in perficientur requisita ex apparatu sub variis operationem conditionibus et variis vitiis et defectum formae, quae possunt esse offendit debet esse plene considerari. Per rationabile consilium, facultatem apparatu defectum per operationem reducitur.

Considerans factores ut materia lectio, structural consilio, muro crassitudine partium calor curatio etc., ut apparatu habet sufficiens vires et rigiditatem ad resistere variis passiones et onerat in opus processus.

Vitare consilio defectus et errores ad redigendum facultatem apparatu defectum.

Select summus qualis materiae et partes:

Select summus qualis materiae, qui occursum nationalibus signa et cubits, et ut key partes venire ex honesta manufacturers ut eorum qualis et perficientur.

Vestibulum processus imperium:

Stricte vestibulum processus elit et inspectionem signa ut processus qualitas cuiusque parte occurrit requisita.

Control et inspectionem per productio confirma qualis est processus ut cito invenire et facientem vestibulum defectus.

II. Sustentacionem et cura

Ordinarius sustentationem et cura:

Ponere et cura apparatu regulariter, reprehendo in operating status in apparatu, et statim invenire et paciscor cum potential culpis.

Reponere graviter attritus partibus et accessiones ut apparatu in bonis operationem condicionem.

Preme lubricatae:

Select oportet Lubricating oleum et lubrication modum secundum opus environment et requisitis in apparatu, reponere in lubricating oleum regularly et emundare oleum cisternina et oleum alveo ut in apparatu et oleum et oleum alveo est ut apparatu est etiam PRAELINO.

III. Cras et diagnosi

Real-vicis vigilantia:

Monitor in operating status mechanica apparatu in ipsa tempore per varios sensoriis, ut celeritate, opus current, vibrationis, ferre temperatus ortum et aliis Indicatores.

Discover: abnormes condiciones in tempore, praestare culpa diagnosis et mane admonitio, et vitare apparatu downtime.

Data Analysis:

Analyze in operating notitia ex apparatu, inveniat de defectum modus apparatu praedicere vita apparatu, et providebit basis ad sustentationem et replacement de apparatu.

Discover: potential problems de apparatu per notitia analysis, optimize et adjust in consilio tempore, et amplius amplio reliability in apparatu.