Quid oportet quod opportunitate Welding modi possunt ad rationabiliter control ad Weld altitudo ad amplio welding qualis?

In WELDING processus, in imperium Weld altitudo est unus de key factores ut welding qualitas. Rationabile Weld altitudo potest non solum amplio vires et corrosio resistentia ad iuncturam, sed etiam optimize altiore perficientur structuram et extend ad ministerium vitae. Ut consequi hoc propositum est maxime momenti ad capere oportet welding modi. Hunc articulum inducere in detail pluribus effective welding modi et applicationes in moderando weld altitudo.

I. Multi-layer multi-saltum Welding

Multi-layer multi-saltum Welding est a technology communiter usus ad densissima laminam welding. Per welding in stratis et transit, penetratio profundum et latitudinem cuiusque layer de Weld potest efficaciter regi, ita avoiding nimia welding altitudo ex calore concentration per unum welding. Processus multi-iacuit multi-saltum Welding, Welder necessitates ad verius posuit welding parametri cuiusque iacuit et pertransit, ut welding vena, voltage, welding velocitate et characteres in latam, welding et characteres in latam, welding situ et characteres in inaestimas, welding situ et characteres in latam, welding et characteres in latam, welding situm et characteres in afrega materia. Per accumulanting iacuit per iacuit, uniformis et firmum tandem formatae, ita ut scampiam altitudo tenetur intra rationabile range.

II. Adductius Welding

Offended welding est a welding modum in quo a welding virga aut welding gun est, swung horizontaliter in welding processus. Hoc welding modum potest crescere weld width et control ad weld profundum ad quaedam quatenus, ita adjusting ad weld excess altitudo. Utilitatem adductius welding est quod potest aequaliter distribute welding calor, reducere loci overheating, et reducere periculum weld rimas et deformatio. Insuper per adjusting adductius amplitudine et frequency, welder potest mollibly control figura et excessus altitudo de weld obviam diversis welding necessitatibus et signa.

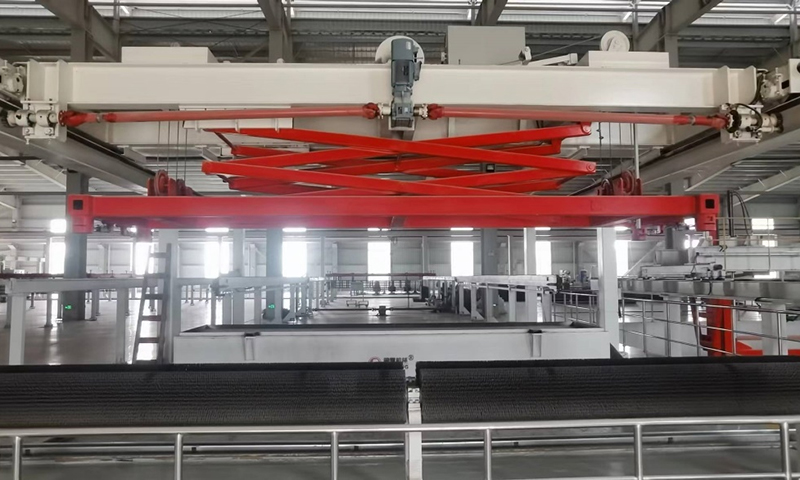

III. Automated Welding Technology

Cum continua progressionem automation technology, automated welding apparatu late in industriae productio. Automated Welding technology potest consequi precise imperium de welding processus, comprehendo in potestate weld excessus altitudinis, per preset welding ratio et parametri. Exempli gratia, in automated TIG WELDING (Tungsten inerti Gas Shielded Welding) vel Mig / MAG Welding (Metallurgical Gas Training Welding Secundum Partes et Partes superfluttorum altitudinis. Automated Welding technology non solum amplio welding efficientiam et qualis, sed etiam reducit dependentiam in arte gradu de welder.

IV. Calefacere Source Concentrated Welding

Nam quidam scaenae ubi de weld excessus altitudo necessitates esse stricte regi, calor fons conuenerunt welding modum potest esse. Hoc modum optimizes et configuratione et distribution de Welding calor fons ut in welding calor acts magis concentredly in Weld area, ita reducendo ad scelerisque impulsum in circuitu parentis materia. Calor fons conuenerunt welding non solum reducere in weld excess altitudinis, sed etiam amplio fusione qualitas et vires de weld. Communis calor fontem conuenerunt welding modi includit summus tech welding technologiae ut laser Welding et electronicum trabem welding.

V. Post-Weld Treatment et Testing

In addition ut eligens idoneam Welding modum, post-weld curatio et temptationis sunt etiam momenti nexus in moderantum weld excess altitudo. Post-Weld treatment includit gradibus ut weld Purgato et molere. Removere impudicitiis nimia excess altitudine in Weld superficiem, species qualitas et dimensional accurate de weld sunt. In eodem tempore, non-perniciosius probatio technologiae talis ut ultrasonic temptationis et radiographic temptationis sunt ad temptare internum qualis est ad rimas et poris. Haec mensuras superiores auxilium ad prompte deprehendere et rectam problems in welding processus et amplio stabilitas et reliability de Welding qualitas.